Why Thermoplastic Elastomer Is a Better Alternative to Silicone

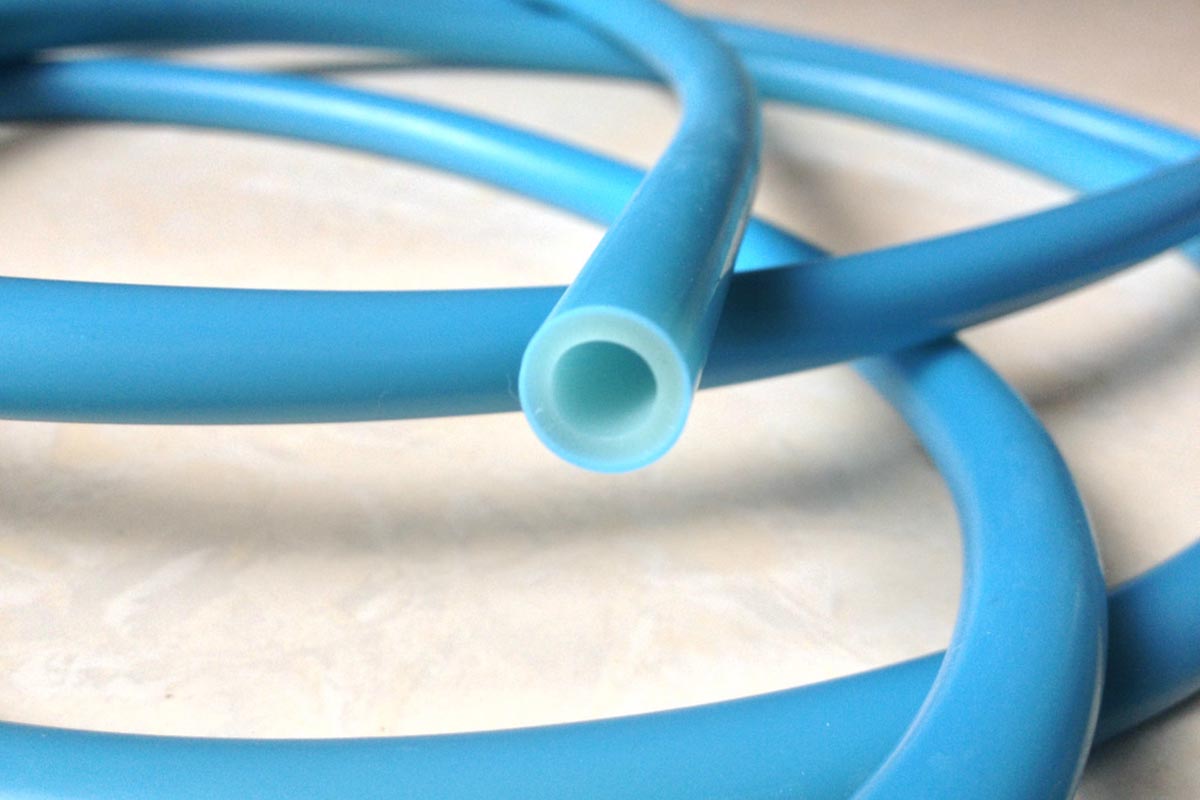

Thermoplastic elastomer or TPE is a solid material that is beneficial for everyday use. Also known as thermoplastic rubbers, TPE is considered as a staple when considering fluid seals in various industries. Its main application is in the manufacturing industry, primarily for molding injection.

A known fact of TPE is its flexibility to be stretched in elongated forms while having the ability to return to its former state. Because of this, it can have a longer product life cycle and has proven to have improved range of physical properties after usage.

Why Use TPEs over Silicone?

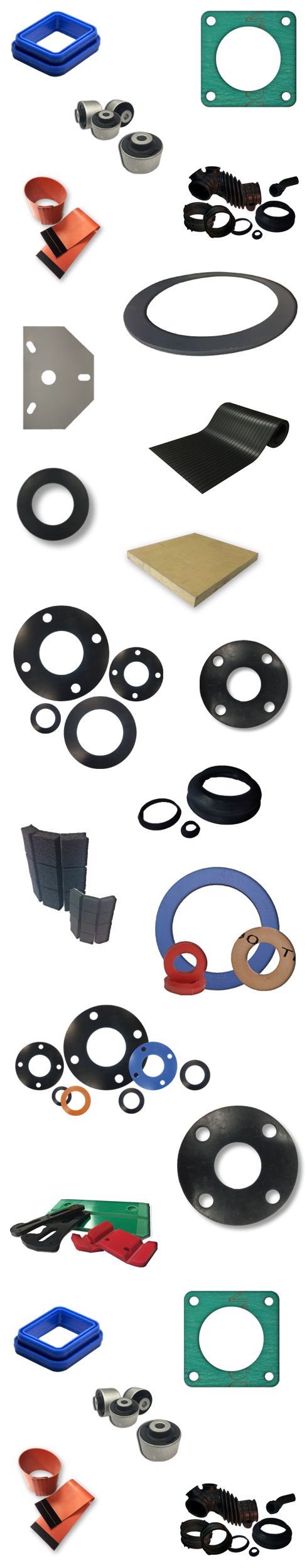

TPEs are prominent for substance stability and excellent thermal properties. They offer greater benefits than silicone for a few reasons. Typically, they are sustainable due to the fact that it’s recyclable, consumes less energy, and provides for economic quality control.

Alongside this, TPEs need not much compounding, resulting to a consistent material among raw components and articles. With their cost-efficient feature, TPEs are a great substitute to silicon rubber. TPEs generally are the excellent materials when it comes to heavy-duty applications such as abrasion resistance, hardness, softness, and more.

TPEs effectiveness in the medical field is also exceptional. Additionally, they are considered great alternatives to latex and this minimizes the environmental problems.