About Us

Innovation is Our Passion

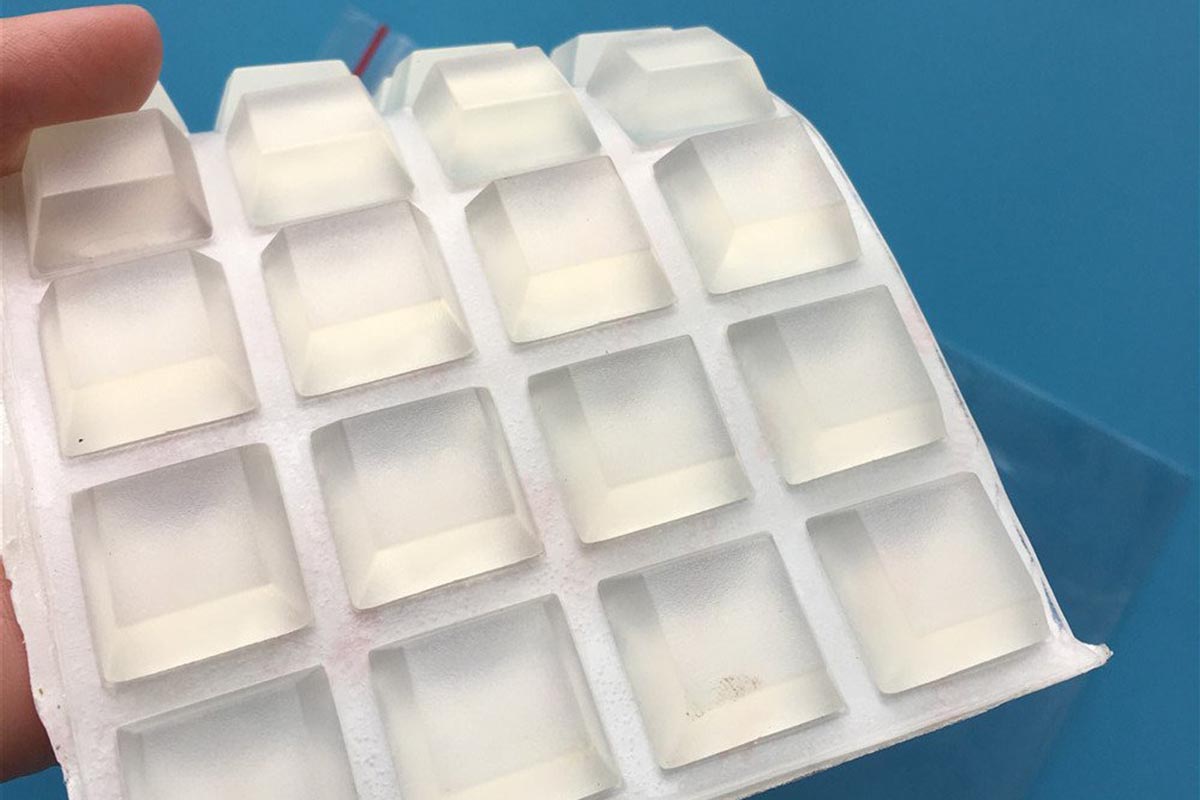

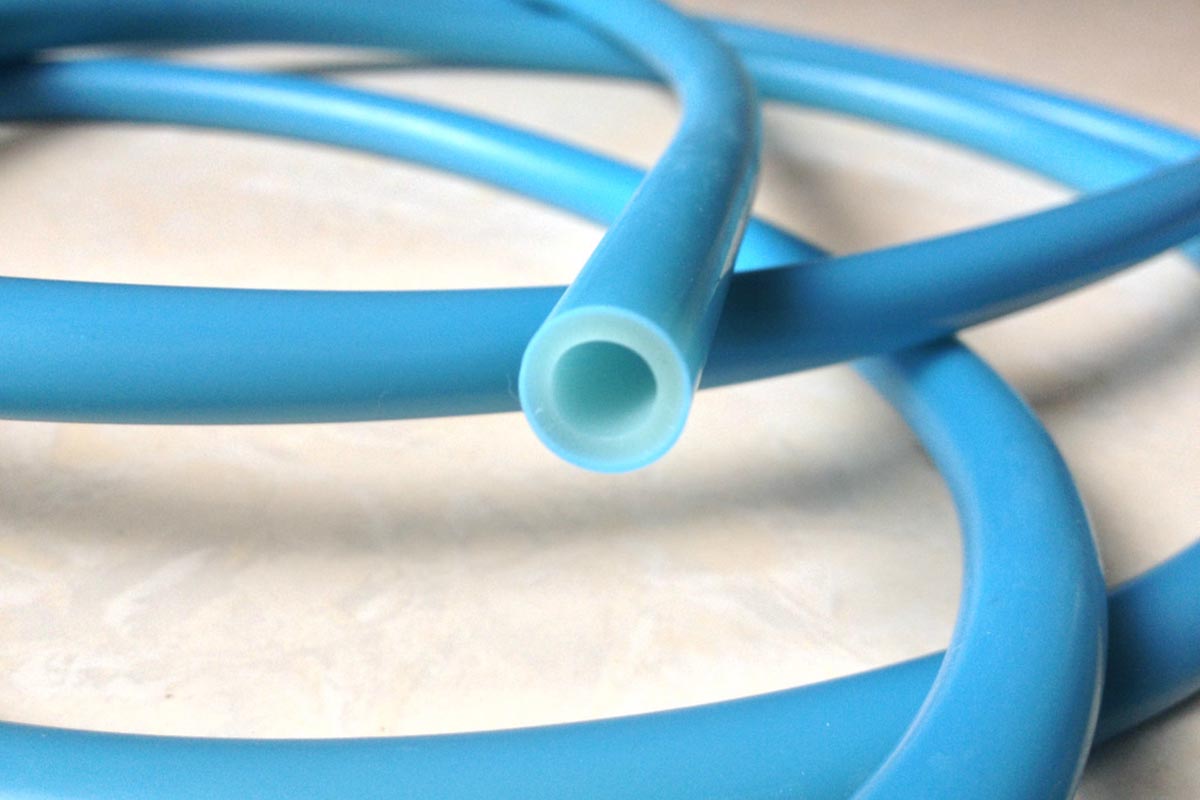

Our starting point stemmed from our belief to deliver only the best to our customers. Sourcing from high-grade materials to going under a compelling team of well-experienced specialists, your project will soar to great heights with our products. We’re an organization that promotes a culture of passion for innovation. Partnering with the best experts, we aim to give you nothing short of the extraordinary whether you are a start-up, SME or large company.

Dedication to High Standards and Value

Here at The Rubber Associates, we value top-notch quality in our…